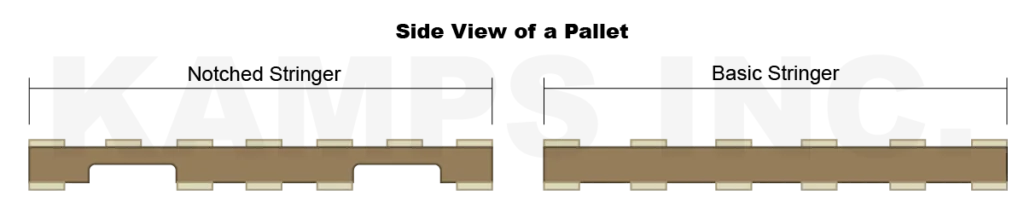

A notched pallet stringer is a type of wooden beam used in the manufacturing of new and recycled pallets that allows for four-way entry on a wooden pallet. Unlike standard stringers with smooth surfaces, notched stringers feature indentations or “notches” along their length. These notches create openings in the pallet deck, allowing for easier forklift access from all four sides.

Click here to learn more about all the parts of a pallet or click here to vist our wood pallets page to see what wooden pallets you can buy from Kamps.

A Brief History of Notched Pallet Stringers

The first wooden pallet was patented in 1924, but significant advancements in pallet design didn’t occur until the mid-20th century, when pallets began incorporating wooden runners (stringers). Click here to read the full 1924 pallet patent. A major breakthrough came in 1977 with Thomas O. Mills’ invention: a machine specifically designed to create notches in stringers. Click here to read about Mills’ invention. Before this machine, creating notched stringers was a laborious task, often done by hand – a time-consuming and potentially inaccurate process. Thanks to this innovation, notched pallet stringers have become the industry standard, offering numerous advantages over their un-notched counterparts.

How a Notched Pallet Stringer is Made

- Harvesting & Processing: Sustainable forestry practices yield the lumber used to create pallet stringers. After debarking and trimming, logs are cut into cants. These cants are then further processed, with each stringer typically utilizing approximately 4.85 board feet.

- Notching & Waste Minimization: Stringers are precisely notched using specialized machinery. Waste material generated during the notching process is repurposed as mulch or fuel pellets, minimizing environmental impact.

- Pallet Integration: Notched pallet stringers are integral components of 4-way pallets. When necessary, companion stringers, often crafted from salvaged material, are used to reinforce existing stringers and extend pallet lifespan.

- End-of-Life Management: At the end of a pallet’s service life, it is dismantled. Salvageable components are recovered, while remaining materials are repurposed as mulch, animal bedding, or fuel pellets.

Key Notched Pallet Stringer Benefits

- Four-Way Entry: The most significant advantage of notched stringers is their ability to facilitate forklift entry from all four sides of the pallet. This four-way entry significantly enhances handling efficiency and reduces the risk of damage to goods during loading and unloading. Click here to read about the key differences between 4-way and 2-way entry.

- Increased Versatility: The open design of notched stringers makes them highly versatile. They are great for pallet handling and can be stacked in various configurations, accommodating different warehouse layouts and operational requirements.

- Improved Stability: While primarily known for their handling advantages, notched stringers can also contribute to improved pallet stability in certain applications. The notches can provide a degree of flexibility in the pallet structure, allowing it to adapt slightly to uneven surfaces.

Industries that utilize notched stringers

- Manufacturing: Ideal for handling diverse products and accommodating various production and shipping processes.

- Warehousing & Distribution: Their four-way entry and versatility make them highly efficient for storage and transportation operations.

- Retail: Widely used to transport and display goods in retail settings, offering easy access for stock replenishment and customer pickups.

- Food & Beverage: Suitable for handling a wide range of food and beverage products, ensuring safe and efficient transportation.

- Construction: Used to transport building materials, offering flexibility and ease of handling on construction sites.

- Other: This list is not exhaustive. Many other industries, including agriculture, pharmaceuticals, and even the automotive industry, utilize notched stringer pallets to improve their material handling processes.

By understanding the unique benefits of notched stringer pallets, businesses can optimize their material handling operations, improve efficiency, and minimize the risk of damage to their goods.

Interested in getting a quote from Kamps on pallets with notched stringers?

Click here to get a quote from Kamps today