A wooden pallet is comprised of three main parts. These components are: top deck boards, stringers (or blocks), and bottom deck boards. These components are fastened together using driven fasteners such as nails, staples, or screws.

Whether you are supply chain leader that makes decisions involving pallets or a fellow manufacturer or recycler, knowing the vital components will help you make better decisions or at least have more meaningful conversations.

This article will define each of the three main components listed and answer some of the most common questions regarding these components. You can also view the video below for a visual on how all these components come together.

Watch: Quick Video Showcasing The Three Main Components of a Wooden Pallet

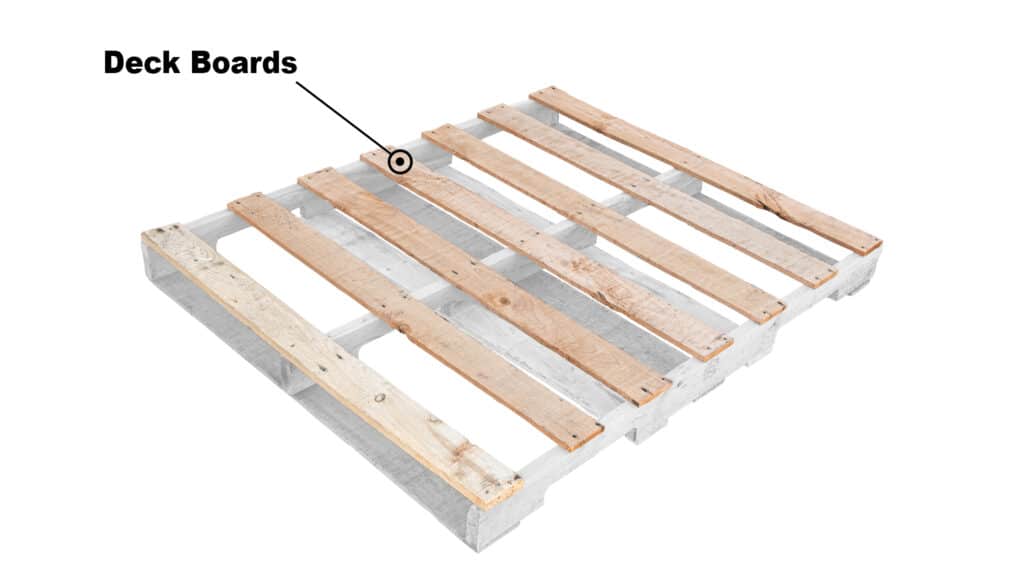

Deck Boards

What are deck boards?

Deck boards are the wooden (flat) boards that comprise the top and bottom of a wooden pallet. They are usually fastened to the wooden stringers using heavy-duty industrial nails or screws. Because products are placed directly onto the deck boards, correct placement and thickness are extremely important. Deck boards can be manufactured out of softwood or hardwood lumber.

The different types of deck board styles

Generally, there are two different types of deck board styles: Standard (the most common) and Wing-Tip. The main difference is the placement of the stringers. Standard deck boards are flush with the side stringers and do not overhang. You can have varying degrees of deck board width in this style. For example, a wide lead 48×40 pallet will have deck boards that are wider at the front and back than the inner boards. Usually, these wide lead boards will be around 5.5-6 inches wide.

A wing-tip pallet consists of indented stringers causing the deck boards to extend beyond the edge of the side stringers, creating a “wing” effect. Wing tips provide extra stability in weight distribution and aids in stretch film application.

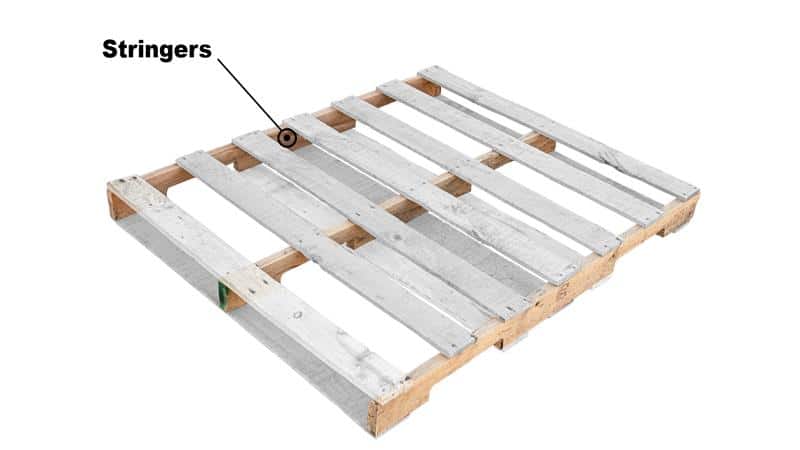

Stringers

What are stringers?

A stringer is the component that sits between the top and bottom of a pallet. Think of it as the patty in a hamburger. It is used to support the top deck boards. It is a continuous, longitudinal, solid, or notched beam component.

Click here to learn more about notched stringer pallets.

Another important detail about stringers is that when discussing dimensions, the stringer length is the first number featured. For example, when discussing a 48×40 pallet, the 48 means that the stringers are 48 inches long.

Importance of stringer placement

Because the main role of a stringer is to support the deck boards of a pallet, and by extension the unit load, they play an important role in the integrity of a pallet. The more stringers a pallet features, the stronger load capacity it will have. This is because adding more stringers shortens the span between each one, therefore reducing top deck deflection. The standard 48×40 GMA pallet features three stringers. However, pallets intended to carry heavier loads can have between four and five stringers.

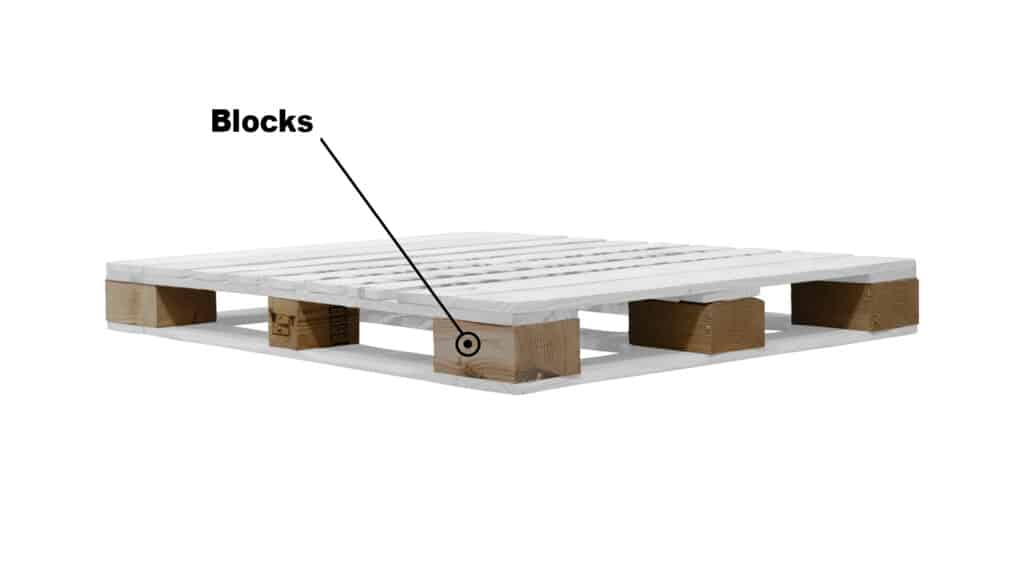

Blocks

Blocks are made from solid wood and support the top deck boards in a wooden pallet while dispersing the unit load across the pallet, similar to stringers. They are typically arranged in a three-by-three grid.

Click here to learn more about which block pallets you can buy from Kamps.

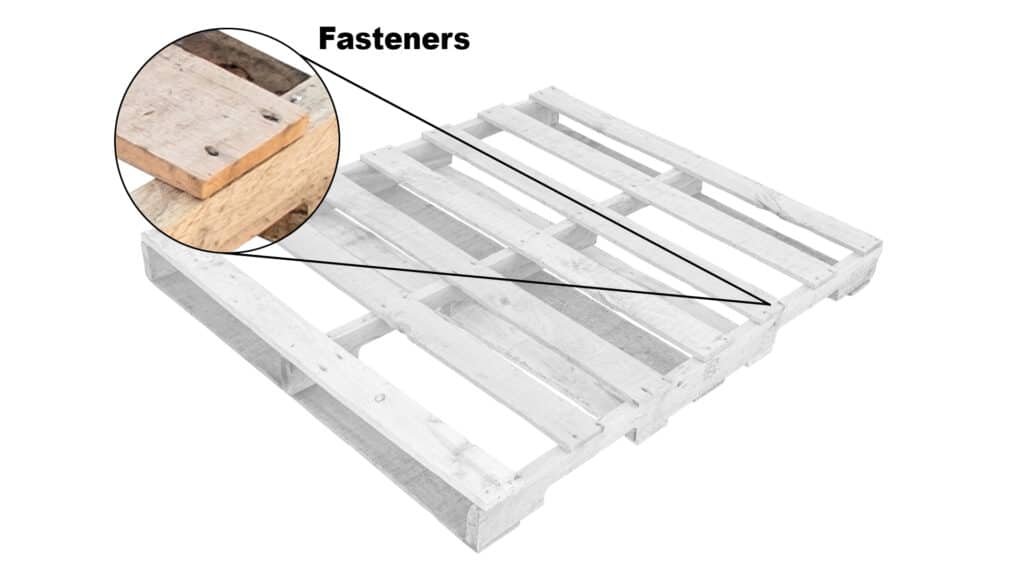

Fasteners

What are the fasteners used in a wooden pallet?

Fasteners, in the realm of pallet manufacturing, are defined as “driven nails and staples, bolts, wood screws, and lag screws”. Driven fasteners include nails and staples. As used in pallets, nails are classified as plain shank, helically threaded, annularly threaded, fluted, or twisted square wire. Staples have either round wire or approximately square wire legs, referring to the cross-sectional shape of the wire.

Which type of fasteners and fastening methods are the best?

There is no straightforward answer to this question as different use cases require different demands. Each type and property of fastener will affect pallet performance and it’s best to consult with your pallet expert on which method and type of fastener is best for your use case.

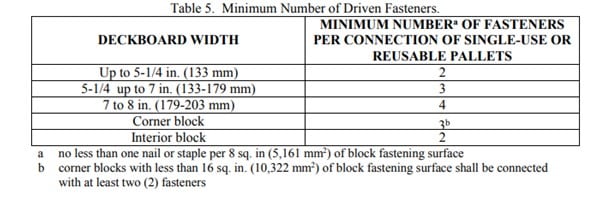

However, a generally agreed upon metric (as set forth by the National Wooden Pallet & Container Association) is the minimum number of driven fasteners based on deck board width. That industry standard is shown below. There may be additional nails based on need or changing industry preference. For example, at the time of this article, nail patterns for interior blocks are typically 3 instead of the 2 shown below in the minimum number of driven fasteners.

Pallet parts found in recycled pallets

Recycled pallets, whether reconditioned or remanufactured, sometimes require strategic repairs in order to restore the integrity of the pallet. Due to these strategic repairs, you may see additional components on a recycled pallet that you wouldn’t on a brand-new product.

Companion Stringers

A companion stringer, also often referred to as a plug, is a piece of a stringer (the vertical wooden piece between the top and bottom deck), that is inserted into a pallet and nailed to an existing stringer. They can come in a variety of size and primarily are used in extending the life of a pallet.

To learn more about companion stringers and their use, click here to read our Everything You Need to Know About Companion Stringers Blog Article.

Watch: Kamps repair specialist demonstrates how to install a companion stringer

Staples

Staples are typically used when repairing minor cracks or damages to the stringer. They also prevent the crack or damage from worsening.

To learn more about the repair process at Kamps, click here to read our In-Depth Pallet Repair Blog Article.