What is a Combo Pallet?

A combo pallet is a common industry term used to refer to a pallet that has been built from used and new components following the pallet recycling process.

These components can be new stringers and used deckboards, or vice versa.

Our systematic process of harvesting used materials and building pallets from these materials follows a standardized process. Because of this standardized process, we can build high quality combo pallets that deliver the results and reliability of new pallets – at a fraction of the cost.

How are Combo Pallets Made?

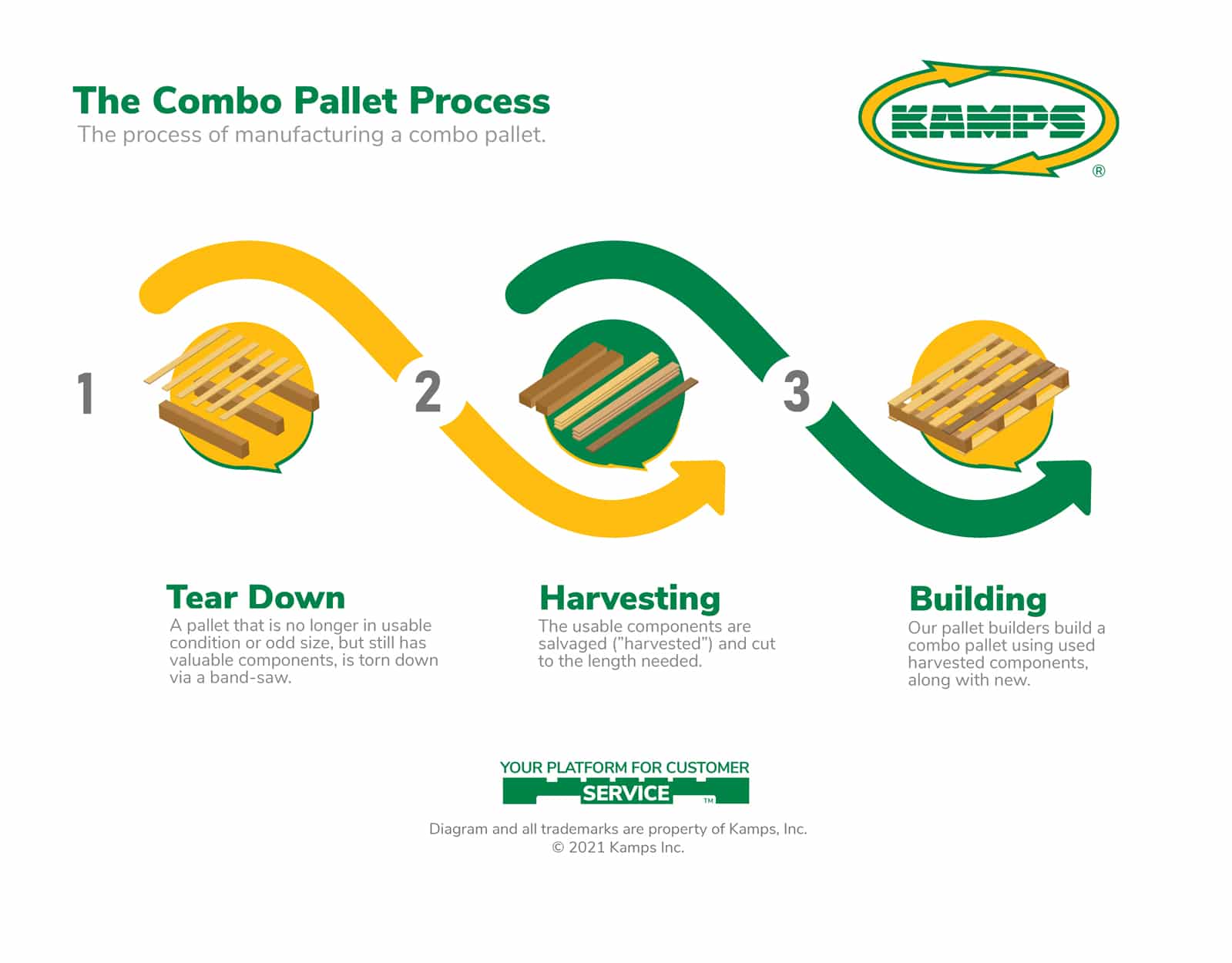

Combo pallets are made through a three-step process:

First, a pallet that is no longer in usable condition but still has valuable components is torn down via a band-saw. This band-saw can be operated by one or two individuals.

Second, the usable components are salvaged (or “harvested”) and cut to the length needed. How this process is executed is varied by location and market.

Last, the harvested components are made available to our pallet builders to use alongside new components when building pallets for customers.

Figure 1: The Process of Creating a Combo Pallet Diagram

What is the Advantage of Using A Combo Pallet?

The primary advantage to using a combo pallet is the pallet’s flexibility in terms of price and specifications.

Used wooden components are more cost-effective than new lumber. Because the combo pallet is built using a mix of new and used components, it carries a lower price point than a completely new pallet.

Because combo pallets are built from the ground up (ie: not repaired), they also have the ability to be manufactured to fit custom specifications. This is extremely advantageous for organizations that may be able to use multiple sizes of pallets and adds flexibility during periods where there may be shortages in the market.

It is important to note, however, that the market can have an effect on both of these characteristics as we are still dealing with used components. The market will still need to produce pallets and components that can support the specifications and dimensions needed.