Deck boards are the wooden (flat) boards that comprise the top and bottom of a wooden pallet. They are usually fastened to the wooden stringers using heavy duty industrial nails. Deck boards serve as the primary support for products being shipped on pallets. Because the importance deck boards play in the pallet’s composition and unit load capacity, they are often one of the main components that are customized when manufacturing a pallet.

There are usually three things that can be customized on a deck board: Width, Thickness, and Lumber Type (Density). All three items carry vast importance in the strength and unit load capacity of a pallet. They also impact pricing. For the purpose of this article, we will be strictly looking at the common practices within the New 48×40 GMA Pallet product category. To learn more about the 48×40 GMA product category, you can read more from our GMA Pallets Guidelines article. To learn more about other standard pallets, you can read more from our Standard Pallet Sizes article.

In the New 48×40 GMA pallet product category, there are multiple varying deck board thicknesses used and only two lumber types.

These deck board thicknesses are:

- ¾ Inch

- 11/16 Inch

- 5/8 Inch

- 9/16 Inch

- ½ Inch

- 7/16 Inch

The 5/8 inch and ½ inch are usually the most common, with 9/16, 11/16, and ¾ inch used in special cases such as market availability and specification need. In regards to how board thickness impacts strength and integrity of the pallet, the common rule of thumb is that the thicker the board the stronger the pallet.

The two lumber densities used are either hardwood or softwood. Common Hardwood species are aspen, cottonwood, oak, hickory, ash, and maple. While all hardwood species, these species all have varying degrees of densities and strengths. Common softwood species are Southern Yellow Pine, Spruce, Pine, and Fir. Similar to hardwood, these species have varying degrees of densities and strengths – all are considered Softwood. Both Hardwood and Softwood lumber may have cosmetic blemishes, such as wane, bark, or small knots. These cosmetic blemishes do not compromise the integrity and strength of the lumber. They may, however, pose challenges if the wooden pallet that uses the lumber with such blemishes needs to be heat-treated for export. Heat-treatment rules and regulations usually only allow for a small percentage of the lumber to be covered in such blemishes. This is because the bark or wane can interfere with the heat-treatment process and not allow the underlying wood to be treated. It is best to consult with your pallet expert on what this percentage is.

To learn more about the differences between hardwood and softwood, you can read our article titled What’s the Difference Between Hardwood and Softwood.

In regards to pricing during a stable market, it is generally accepted that thicker deck boards are higher in price and that hardwood is higher in price than softwood. Supply and demand in the local and national markets can affect these statements.

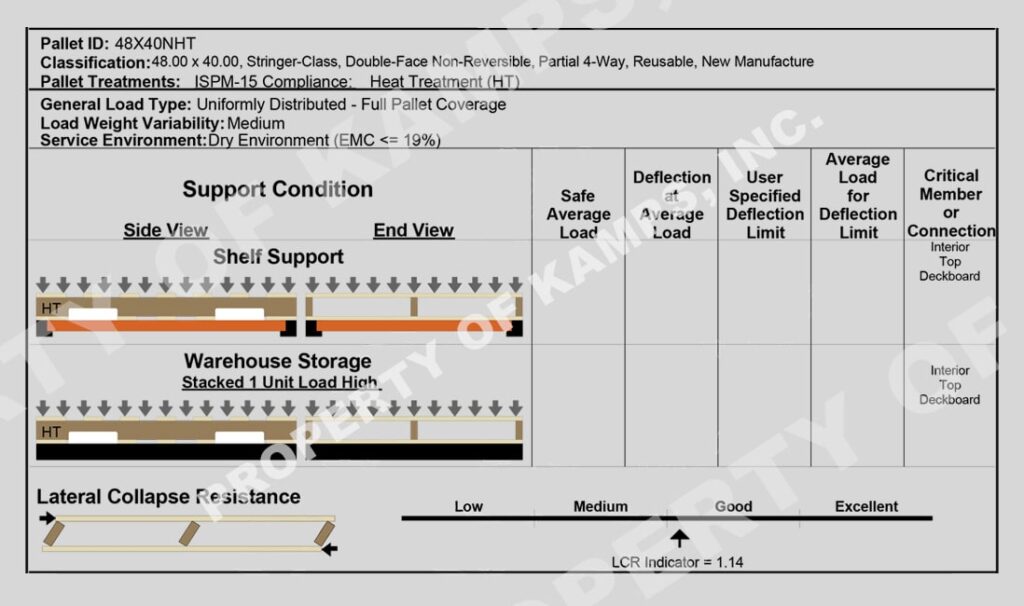

Chart Illustrating Impact of Thickness and Lumber Type on New Pallet Strength

We worked together with our experts to use industry leading Pallet Design System to create the following chart below that illustrates the impact of both deck board thickness and lumber density.

Disclaimer: The pallet used below was a New 48×40 GMA Wooden Pallet. All elements outside of board thickness and lumber type were unchanged (controls). This includes stringer characteristics, fastener placement, etc. The following graph is for educational purposes only and should not be utilized as guidance to making pallet decisions. Elements, such as unit stacking height and unit shapes can skew support conditions. It is highly recommended and encouraged to speak with a Kamps PDS expert prior to making board thickness and lumber type decisions when building a new pallet.

| Board Thickness | Lumber Type | Shelf Safe Avg. Load* | Shelf Deflection at Avg. Load* | Warehouse Safe Avg. Load | Shelf Deflection at Avg. Load |

| 3/4 Inch | Hardwood | 4571 lbs | 0.14 in | 5651 lbs | 0.17 in |

| 3/4 Inch | Softwood | 3535 lbs | 0.09 in | 4438 lbs | 0.12 in |

| 5/8 Inch | Hardwood | 3244 lbs | 0.15 in | 4011 lbs | 0.19 in |

| 5/8 Inch | Softwood | 2497 lbs | 0.10 in | 3135 lbs | 0.12 in |

| 9/16 Inch (0.563) | Hardwood | 2685 lbs | 0.16 in | 3320 lbs | 0.20 in |

| 9/16 Inch (0.563) | Softwood | 2061 lbs | 0.10 in | 2587 lbs | 0.13 in |

| 1/2 Inch | Hardwood | 2181 lbs | 0.17 in | 2696 lbs | 0.21 in |

| 1/2 Inch | Softwood | 1668 lbs | 0.11 in | 2094 lbs | 0.14 in |

*2 Beam Rack with Shelf Support used in example. These numbers and figures can vary based on what type of racking system is utilized to support the pallet.

Strategically using deck board thickness and density to improve pallet programs

When building a new pallet program, Kamps experts will analyze all aspects of a customer’s supply chain and build a program that brings the best value in regards to price, quality, and environmental sustainability.

Board thickness and density can be used strategically to achieve the best results in all three categories.

For example, your supply chain may be utilizing a 5/8-inch softwood pallet. After careful analysis, it may be proven that a ½ hardwood pallet may provide the performance needed for your unit load – at a lower cost. This also provides a positive environmental impact as switching to 1/2 inch (0.50″) from 5/8 inch (0.625″) saves on average 1.8 bd ft per pallet. Per an average load of pallets (400 per truckload) this equates to ~720 bd ft per load of pallets saved. The average volume of board feet generated by the average aspen tree is approximately 100 bd ft. This means the simple switch from 5/8 inch board thickness to 1/2 board thickness has the opportunity to save 7 trees per average pallet load.

Board Feet Saved Sources: USDA Forest Service, 8 Billion Trees

Choosing the correct deck board thickness and lumber type

The information provided in this article is intended only to be used as a high-level overview of the impact deck board thickness and lumber density can have on new wooden pallet. There are many nuances within a supply chain that can make decision-making more challenging.

For example, while on the surface a ½ inch deck board may require less lumber than a 5/8 inch. However, in the long run, a 5/8-inch new pallet may be more environmentally sustainable due to the increased number of trips in can withstand. The number of trips obviously depends on the way the pallet is handled and used within the supply chain. The average life of a pallet can also vary based on the pallet company of choice the supply chain partners with.

These scenarios and nuances can go three of four layers deeper. This is why there truly does not exist a simple “if” “then” statement for choosing the right deck boards for your supply chain. Furthermore, it underscores the important role Kamps plays in maximizing the value of your supply chain.

We are the industry leaders in Comprehensive Pallet Life-Cycle Management. That means supply chain leaders trust us to develop the perfect pallet program for them. One that is aimed at extending and adding value to the entire life-cycle of their pallets – from when it is designed as a new pallet to when it becomes a sustainable byproduct.

Contact our experts today to learn more about how our Comprehensive Pallet Life-Cycle Management capabilities can add value to your supply chain.

Comprehensive Pallet Life-Cycle Presentation Video