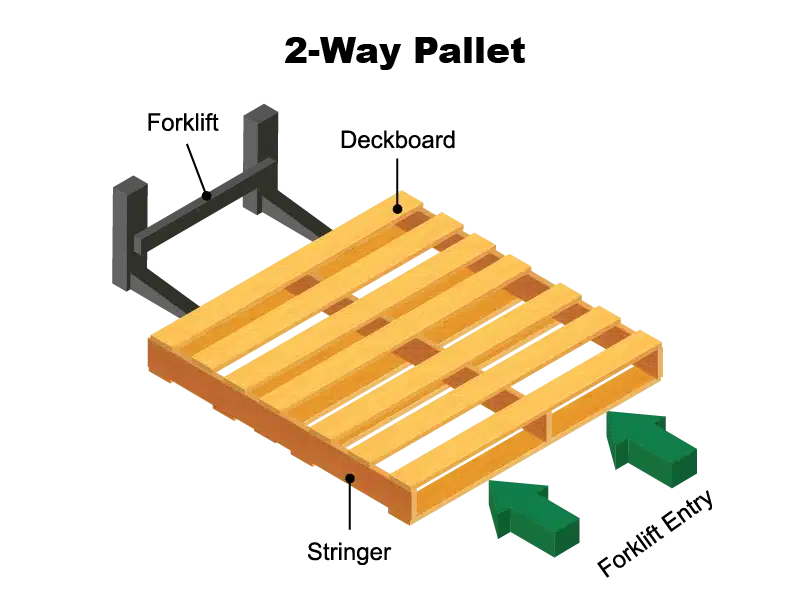

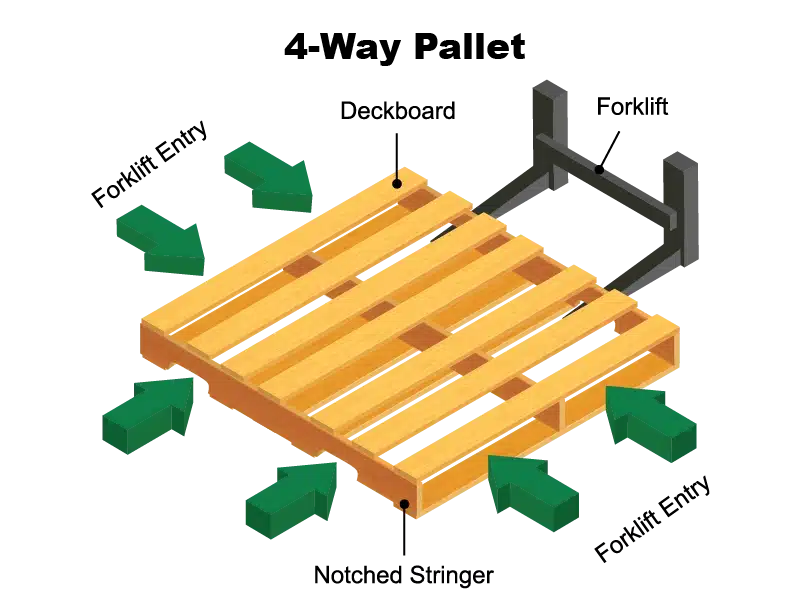

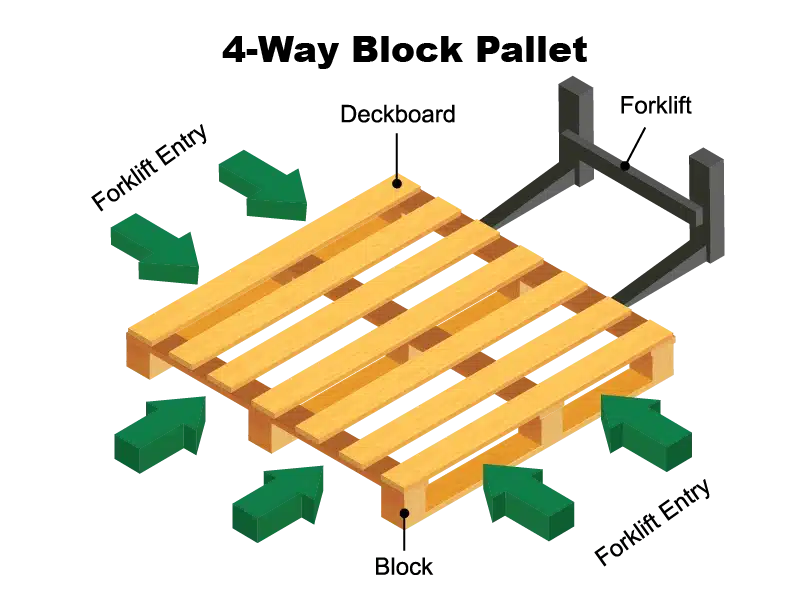

The difference between a 2-way and 4-way pallet is entry and appearance. A 2-way wood pallet allows a forklift or pallet jack to pick up the pallet from two sides, while a 4-way pallet allows access from all four sides.

Because of this, the appearance of a 2-way and 4-way pallet varies. Both pallets will allow entry from the “front”, which is the short side of the pallet. 2-way pallets will use solid stringers on the side (stringers are shown in the image below). Stringers are the vertical wooden boards that run between the top and bottom deck boards of a pallet. This is what prevents the forklift or pallet jack from entering from the side. 4-way pallets will either use notched stringers or blocks to essentially create an opening on the side of the pallet, allowing for access on all four sides.

The Pros and Cons of a 2-Way Pallet

| Pros | Cons |

| Enhanced Durability: Because the stringers in a 2-way wooden pallet are solid from end to end, they are usually stronger and less prone to breaking than notched stringers. Lower Cost: Because the design of a solid stringer 2-way pallet is much simpler, it will usually carry a lower cost than its notched or block pallet counterpart. However, it is important to note that this is only true for 1:1 specification replicas where all other conditions are the same. | Lower Efficiency: Because a 2-way pallet can only be accessed from two sides, your warehouse and operations employees will have to spend more time maneuvering around the pallets in order to move and/or lift them properly. Supply Chain Space Utilization: Whether in your warehouse or during transit, the lack of access from the sides will need to be accounted for at all points within your supply chain. This means special storage arrangements within your warehouse and special storage arrangements when transporting via truck are required. Both of these will lead to decreased space utilization. |

The Pros and Cons of a 4-Way Pallet

| Pros | Cons |

Supply Chain Space Utilization: Because forklift and pallet jack entry can occur from either sides, a 4-way pallet gives your supply chain ultimate space utilization. They do not require special storage orientation. When transporting a load using 4-way pallets you also maximize the space of your trailer and can load more pallets per truckload. Increased Efficiency: Because warehouse and operations employees can access the pallet from all sides, less time is being spent maneuvering around the pallet. Lower Labor Cost: Due to the increased efficiency and speed at which your employees can load and unload shipments, a 4-way pallet creates the potential for decreased labor costs. | Potential for Decreased Durability: Notched 4-way pallets create an opportunity for your employees to weaken and damage the pallet from the side due to employees improperly entering the pallet. We recommend training your pallet handling employees properly to prevent unnecessary damage and extend the life of your pallet. Click here to read a research paper from Virginia Tech on the different hazards experienced by pallets during material handling. Higher Cost: Because of the additional process of creating a notch or manufacturing a block pallet, most 4-way entry pallets will cost more than their 2-way counterparts. Again, other specifications can be changed to lower costs, if necessary. |

Which one is recommended for your supply chain?

There is no straightforward answer to this question as it all depends on your supply chain and the needs of your business. However, you can begin to form an opinion by utilizing our pros and cons charts and comparing them to your own supply chain and the needs of your business.

If you are still not sure, we recommend reaching out to one of our pallet experts to begin a consultation that will analyze the exact needs of your supply chain. For example, while a 4-way pallet may seem pricier on the surface, our experts can alter other specifications (click here to learn more about our custom pallets), find substitutes to meet your budget or offer a cost savings analysis that considers things such as lower labor cost and pallet resale value.