Warehouse Layout is important because it can directly impact the efficiency and profitability of your operations.

Having over 40 years of experience in the Pallet Industry, Kamps has seen thousands of warehouses and worked with customers big and small.

Our methods to improving your warehouse layout is the culmination of these years and what we know works.

Kamps Recommended Methods to Optimize Your Warehouse Layout:

- Consistently Optimize “Pick Paths”

- Short and Wide Aisles

- Optimized Racking

Review “Pick Paths” on a regular basis

A Pick Path refers to the route a picker takes through the picking area to complete his picking tasks. Depending on the nature of your business, picking can take up to 50% of your warehouse operations.

A poorly designed pick path cause a drop in overall efficiency of your warehouse, and raise costs. This mostly occurs due to warehouse staff having to back-track, perform extra motions, and travel long distances while assembling orders or loading trucks.

The need to review pick paths is important because over time your warehouse operations, layout, or products may change. A path that was efficient and lean before may not be as efficient now. It is a good idea to review pick paths from time to time and make the necessary changes to improve efficiency and keep labor-related costs down.

Short and Wide Aisles

A warehouse with endless rows of racking may be impressive at first glance, however, this type of warehouse layout is not good for efficiency or costs.

Time is money.

If it takes your warehouse employees a long time to get from one area of your warehouse to another, your current set up is most likely inefficient.

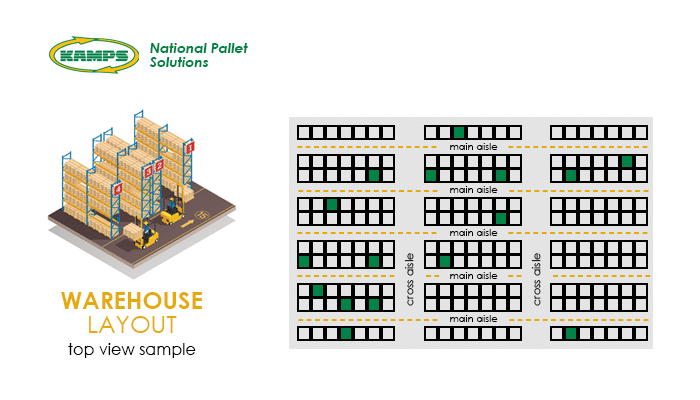

Consider implementing more cross aisles and shortening the aisles to improvement flow and lower distance between your products. Doing this can potentially cut pick path routes in half. You will also increase the speed of product retrieval and truck loading.

Widening aisles will help with preventing pallet damage and damage to your products. Remember, an optimized warehouse layout is not just about speed – it is also about protecting your assets.

Here is an example of what a warehouse layout with optimized aisles looks like:

Optimized Racking

Pallet racks are a great way to optimize storage space. However, using the wrong kind of racking for your building can have a negative effect on the layout of your warehouse and costs.

For example, if your products are heavy, you will want to go with a full-fledged pallet rack. However, if your products do not weigh a lot, you may be able to get away with Heavy-duty shelving – which is much more cost effective.

When choosing a pallet rack, here are some other things to consider:

- Height utilization

- Floor Utilization

- Need for Flexibility: Will the size and shape of your products stay consistent? If not, consider investing in racking systems that are easier to adjust.