The Case Study

This case study highlights the impact Kamps’ expertise, resources, and innovative spirit can have on even the most complex supply chains to bring about cost savings, time savings, and increase transparency. This case study highlights Kamps’ comprehensive approach to pallet solutions. The analysis and problem-solving process included in this case study is an example of the approach our experts take with every pallet program – large or small. It is also important to note that every program and supply chain is unique and the benefits and solution in this process may not apply to every scenario. This is exactly why Kamps’ expertise and know-how is invaluable in regards to pallet program improvement and analysis, regardless of whether you’re in the automotive industry or not.

The Situation

Two leading players in the automotive industry are faced with similar challenges in their respective pallet management programs. Both companies have decentralized pallet purchasing strategies, allowing locations to independently procure pallets from various sources. This led to a lack of clear visibility on the final destination of these pallets once they were used and a general lack of understanding of the pallet program. This resulted in substantial annual expenditures as they ordered pallets from various suppliers, and often ordered new pallets to support their shipping operations. The lack of a streamlined process and sustainable practices posed financial and operational hurdles for both automotive giants.

Opportunity for Improvement

After a period of analysis, the Kamps team identified several key areas that required attention. These included reducing pallet purchasing costs, enhancing visibility into pallet movements, promoting sustainability through the use of recycled materials, and establishing a comprehensive framework for pallet management across their respective supply chains.

The Solution

To address these challenges, Kamps offered a holistic solution that encompassed pallet procurement, asset recovery, remanufacturing, and recycling. By partnering with Kamps, both companies aimed to streamline their pallet management processes, lower costs, and achieve greater transparency throughout the pallet lifecycle through a singular closed-loop pallet program. One of the automotive companies had an Order Portal created by Kamps, allowing them to purchase pallets from any of their locations, receiving the order within 24-48 hours. The second automotive company gave Kamps complete access to all of their facilities, creating the opportunity to pinpoint all of their pallet waste. This created a new stream of pallet components that could be used for their recycled pallet purchases, greatly decreasing their overall cost.

Kamps’ Unique Advantage

Kamps brought several unique advantages to the table that set them apart from other pallet suppliers.

1. The ability to easily scale up production and deliver high-quality pallets aligned with the automotive companies demanding supply chain requirements.

2. The expertise in pallet asset recovery allowed them to retrieve and reintroduce pallets from various sources, reducing the need for new pallet purchases.

3. Kamps’ advanced technology and industry-leading equipment enabled them to incorporate recycled materials into pallet production, ensuring sustainability while keeping costs low.

4. Proprietary comprehensive portal provided total pallet management transparency, while their Green Scorecard facilitated sustainability reporting, enhancing corporate stewardship for both parties.

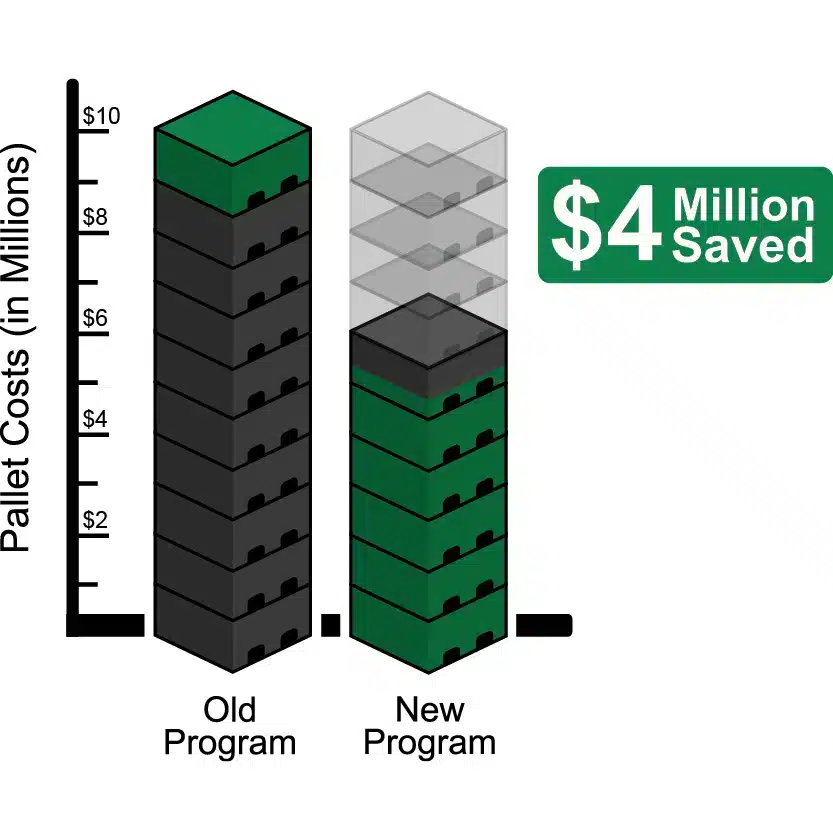

Case Study Results

Partnering with Kamps on a custom closed-loop program enabled the two automotive companies the ability to decrease overall shipping costs and greatly increase nationwide visibility between facility locations and their respective program. The streamlined ordering process also freed up vast amounts of time for their staff, allowing the employees to shift focus solely on higher priority tasks.

Cost Reduction

Cost Reduction

Increased Visibility

Increased Visibility

Time Savings

Time Savings