What is the Standard Pallet Size?

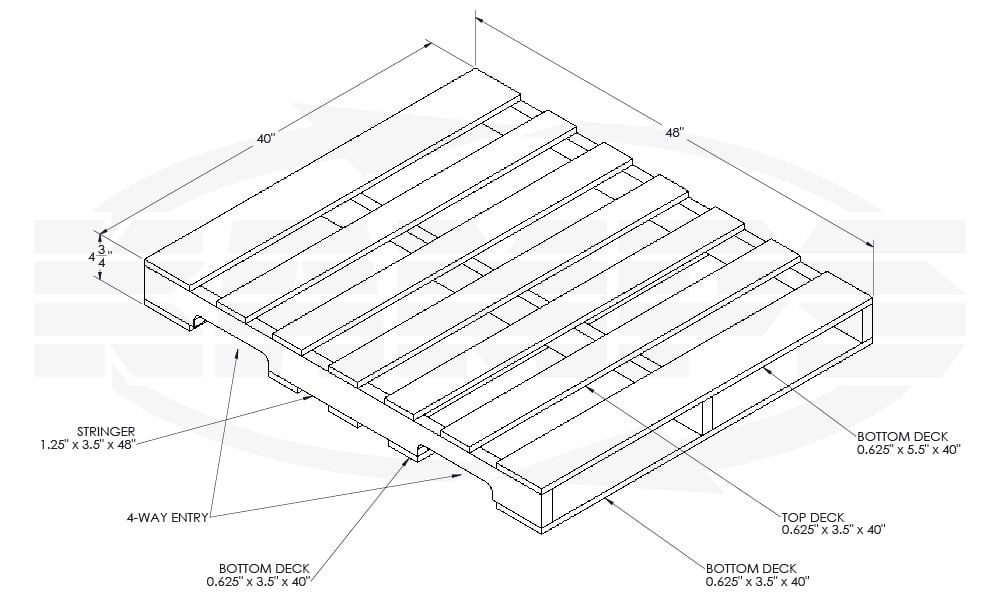

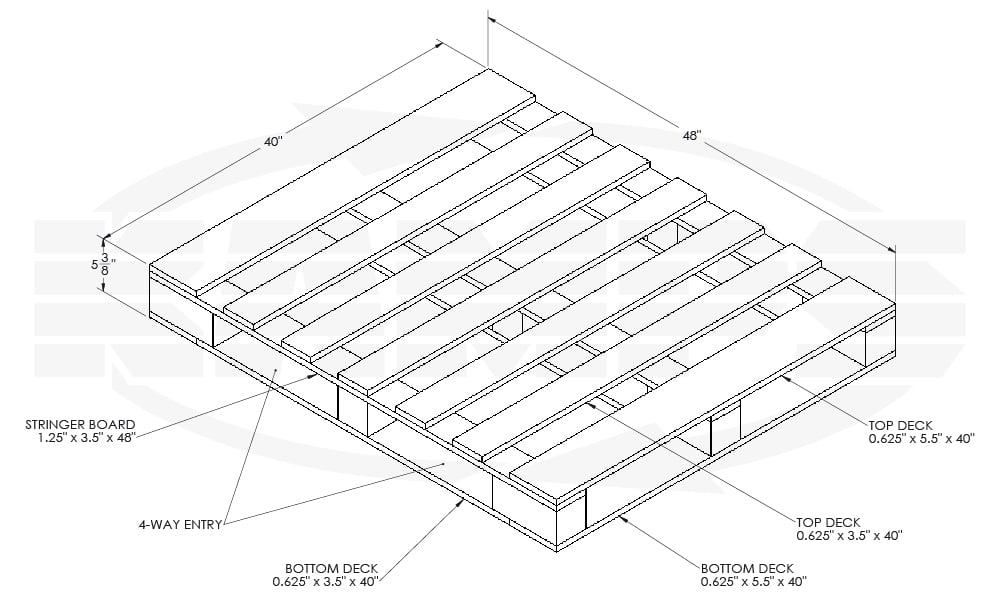

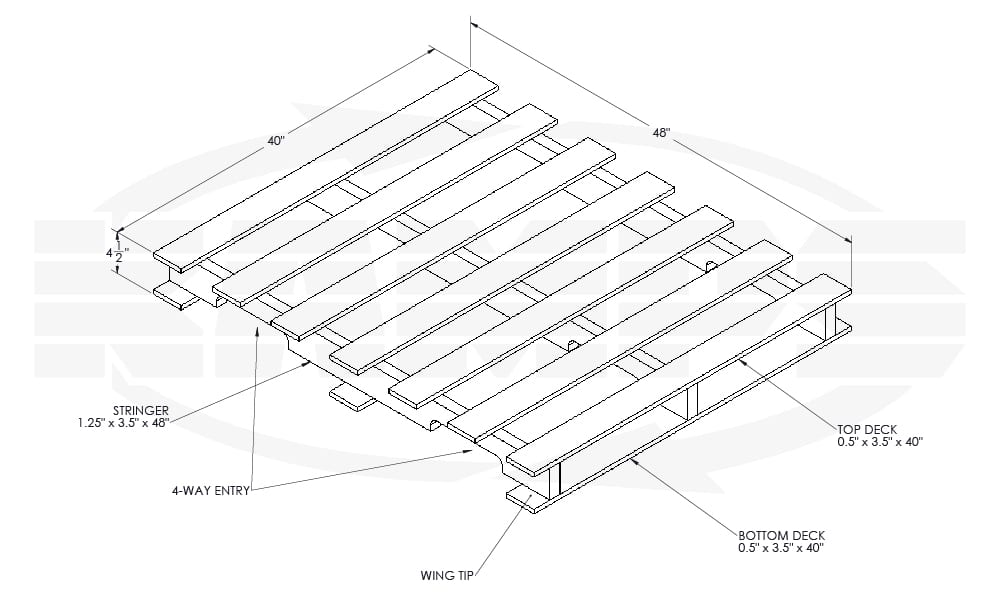

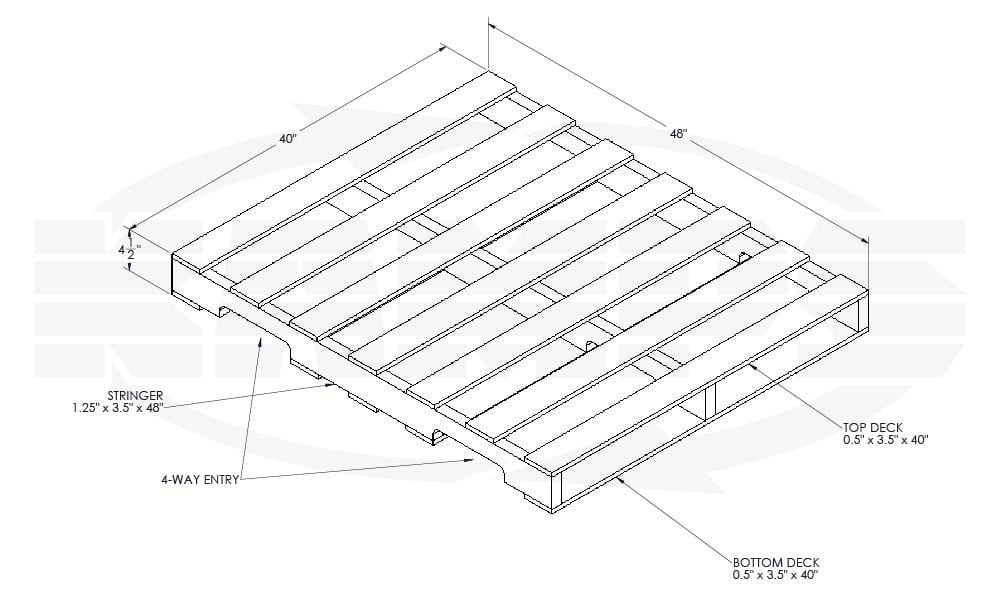

When individuals refer to the “Standard Pallet Size” in the United States, they are typically talking about the GMA 48” x 40” (seen in the photo below). Specifications for this pallet are generally 3.5-inch-wide and 1/2-inch-thick deck boards. Around 30% of all new wood pallets produced in the United States fall into this category. The 48” x 40” pallet is commonly used in grocery, general warehousing, and storage.

Standard Pallet Sizing Chart

| 48×40 |

| Top Deck Number: 7 Bottom Deck Stringer Number: 5 Safe Maximum Load: 4592 lbs Average Pallet Weight: 37lbs | |

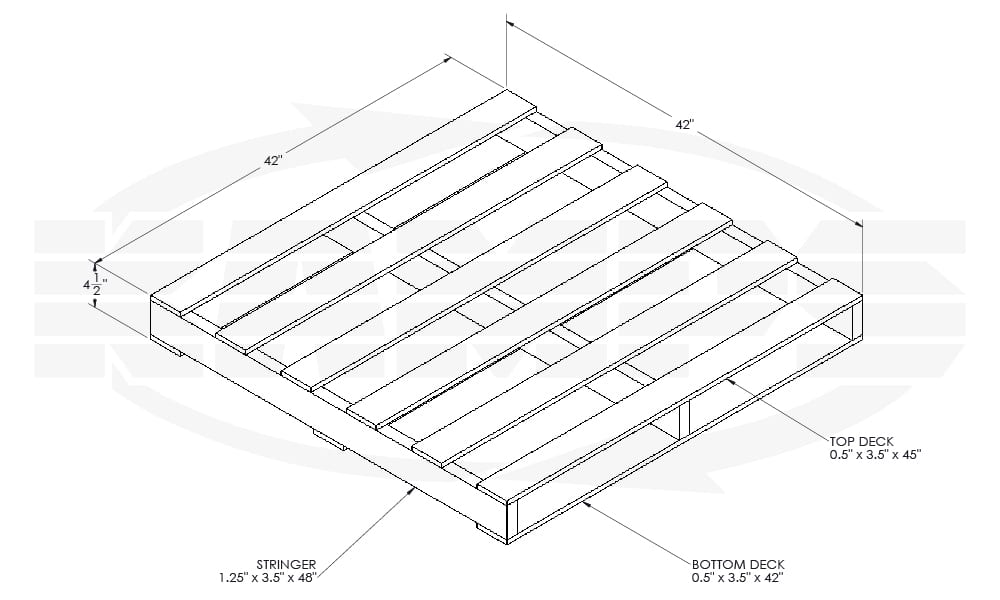

| 42×42 |

| Top Deck Number: 7 Bottom Deck Number: 4 Stringer Number: 3 Safe Maximum Load: 4445 lbs. Average Pallet Weight: 36 lbs. | |

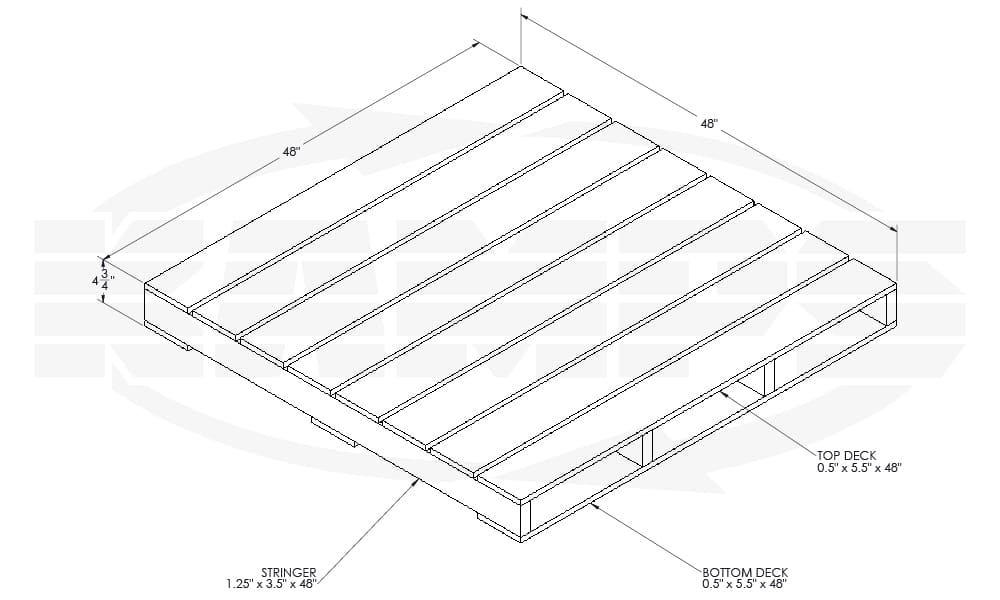

| 48×48 |

| Top Deck Number: 6 Bottom Deck Number: 3 Stringer Number: 3 Safe Maximum Load: 4673 lbs. Average Pallet Weight: 37 lbs. | |

| 40×48 |

| Top Deck Number: 7 Bottom Deck Number: 4 Stringer Number: 3 Safe Maximum Load: 3696 lbs. Average Pallet Weight: 42 lbs. | |

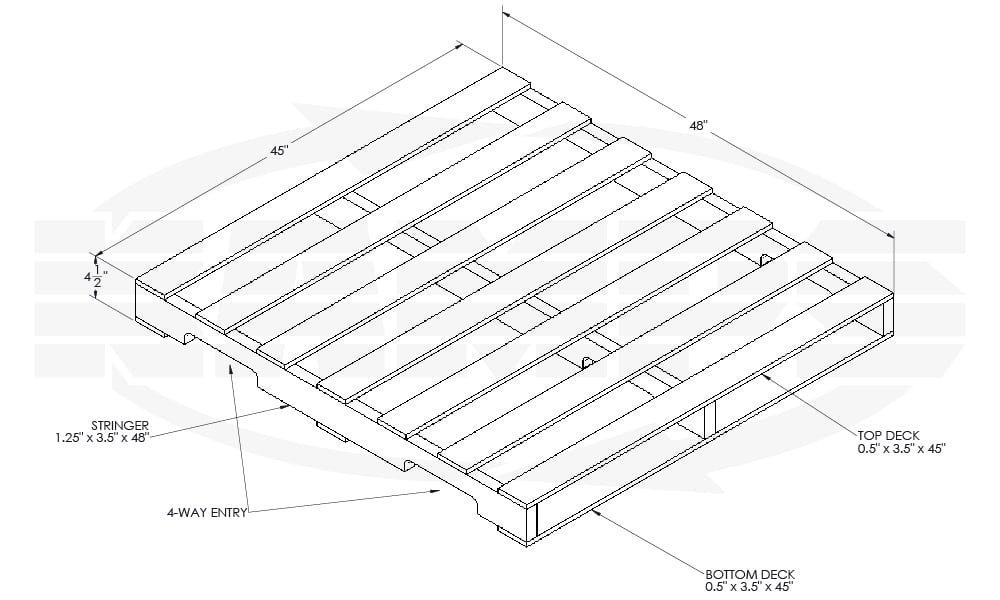

| 48×42 |

| Top Deck Number: 7 Bottom Deck Number: 4 Stringer Number: 3 Safe Maximum Load: 4333 lbs. Average Pallet Weight: 35 lbs. |

| 40×40 |

| Top Deck Number: 6 Bottom Deck Number: 3 Stringer Number: 3 Safe Maximum Load: 3544 lbs. Average Pallet Weight: 29 lbs. | |

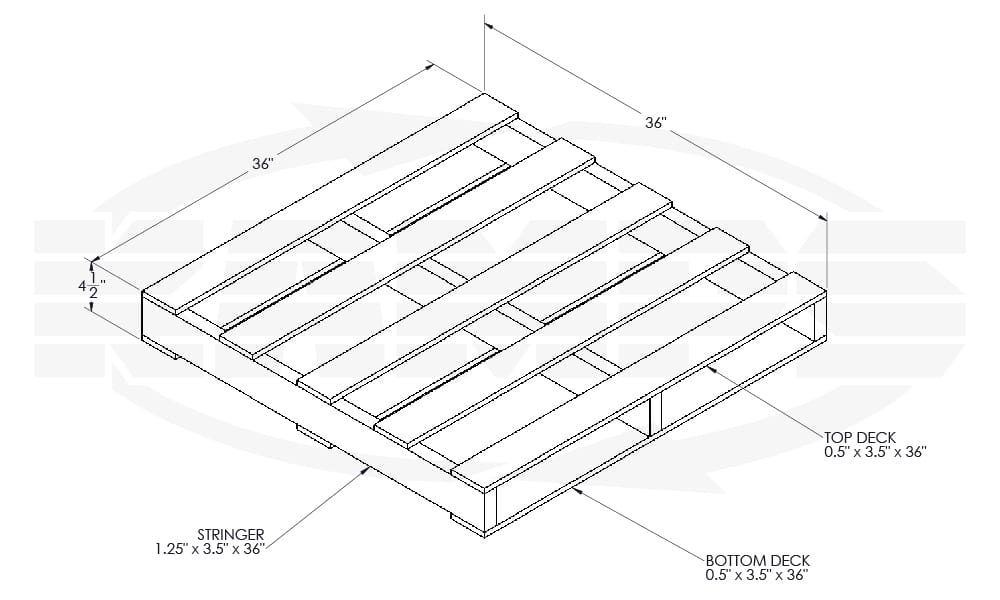

| 36×36 |

| Top Deck Number: 6 Bottom Deck Number: 4 Stringer Number: 3 Safe Maximum Load: 3544 lbs. Average Pallet Weight: 32 lbs. | |

| 42×31 |

| Top Deck Number: 6 Bottom Deck Number: 4 Stringer Number: 3 Safe Maximum Load: 6585 lbs. Average Pallet Weight: 33 lbs. | |

| 48×36 |

| Top Deck Number: 6 Bottom Deck Number: 3 Stringer Number: 3 Safe Maximum Load: 5261 lbs. Average Pallet Weight: 31 lbs. |

Click here to download a summary PDF

Other Common Pallet Dimensions

The other two most popular standard pallet dimensions in the United States are the:

- 42” x 42” pallet (Sometimes referred to as a “42 Square”)

- 48” x 48” pallet (Sometimes referred to as a “48 Square”)

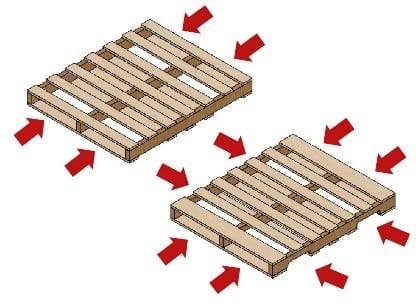

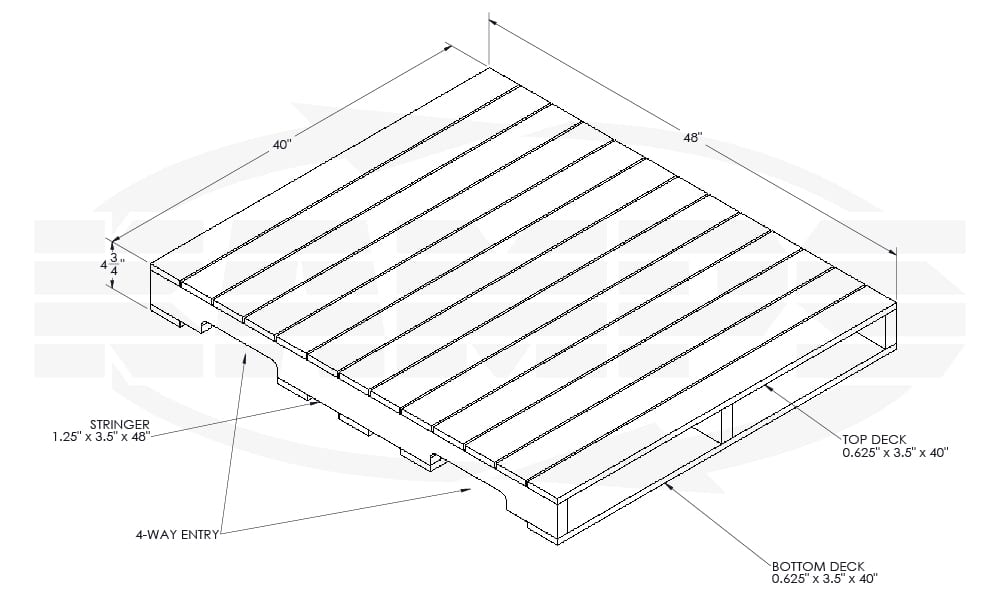

Both of these pallets can be two-way or four-way, which indicates what direction the pallet jack or forklift can enter. In the picture below, the two-way pallet is shown in the top image, while the four-way pallet can be seen underneath. Click here to learn more about the difference between 2-way and 4-way pallets.

The History of The 48×40 Standard Pallet

The standard 48” x 40” pallet was first introduced by the Grocery Manufacturers Association, now going by the name of Consumer Brands Association. The purpose of the standard pallet was to allow goods transported in the United States to be handled efficiently and easily from one distributor to another. By having a standard, agreed-upon pallet size, groceries, and retailers can standardize their shipping and distribution. Having a standard pallet size also decreases the amount of wasted space, while allowing both forklifts and pallet jacks to move with ease. This makes it the preferred pallet for groceries.

48×40 Standard Pallet Weight, Capacity, and Height

The standard pallet is about 4 ½ inches tall. The top and bottom deck boards are ½ inch, and the stringers take up 3 ½ inches of height.

The load capacity of the pallet can depend on many factors such as block or stringer and the number of blocks or stringers. However, the standard 48” x 40” pallet with 5/8” wood thickness can hold up to 4,600 lbs. This makes it an ideal pallet for grocery or retail.

Learn more about pallet weight by reading our post, ‘How Much Does a Pallet Weigh?’

Standard Pallet Materials

There are many different types of materials used to make pallets but the main material that stands out for its widespread use and inherent qualities is wood. Wood has become the industry standard due to its distinct advantages and suitability for various applications.

Constructed from various types of lumber, these pallets are commonly used in industries where cost-effectiveness is a priority, such as manufacturing, warehousing, and logistics. Their durability makes them suitable for carrying heavy loads, including machinery, construction materials, and bulk goods. Wood pallets can easily be customized in size and overall design to suit specific needs, adding to their widespread adoption. Another advantage is the ability to repair them; damaged boards can be replaced, extending the pallet’s lifespan and again, saving costs. Wood pallets are also often preferred for international shipping, especially when goods need to be stacked securely. They are also recyclable and can be repurposed or used as biomass fuel at the end of their life cycle.

There are other options, such as plastic and corrugated. However, the challenges with using these types of pallets make them a preferable choice only in specific scenarios and niche use cases.

(Read our blog post about the difference between wooden and plastic pallets here)

Standard Pallet Types

Depending on the country and use case, many different variations of a standard pallet can be available. Below are the three basic configurations.

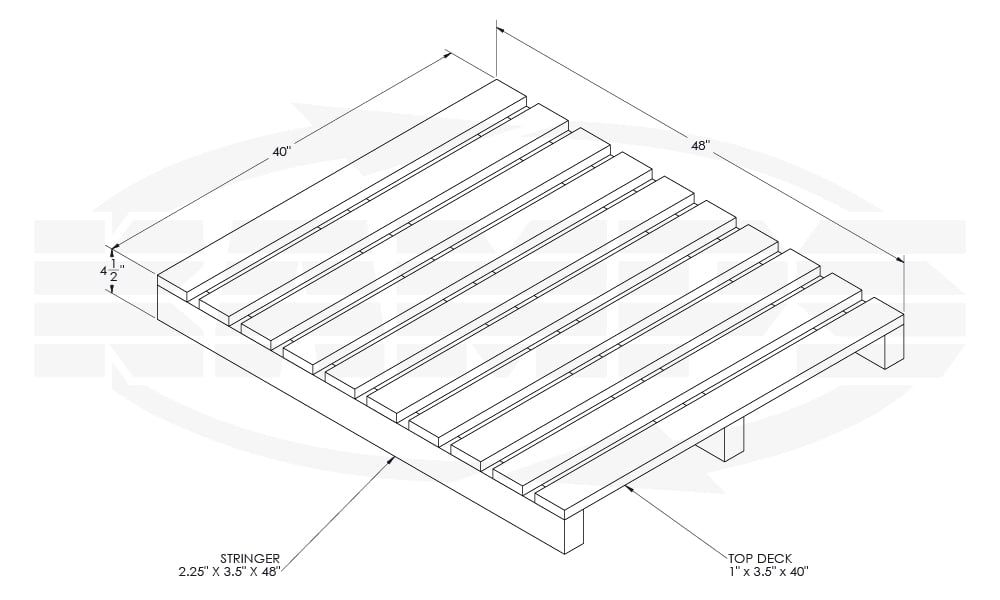

Stringer

Stringer Pallets are one of the most common pallet types used in logistics and warehousing. They are characterized by the use of stringers – horizontal 2×4” boards that span the space between and parallel to the top and bottom deck boards. These “stringers” are typically arranged in a configuration of 3, providing support and stability. They can be notched (partial four-way entry) or unnotched (two-way entry), allowing easy access for forklifts and pallet jacks.

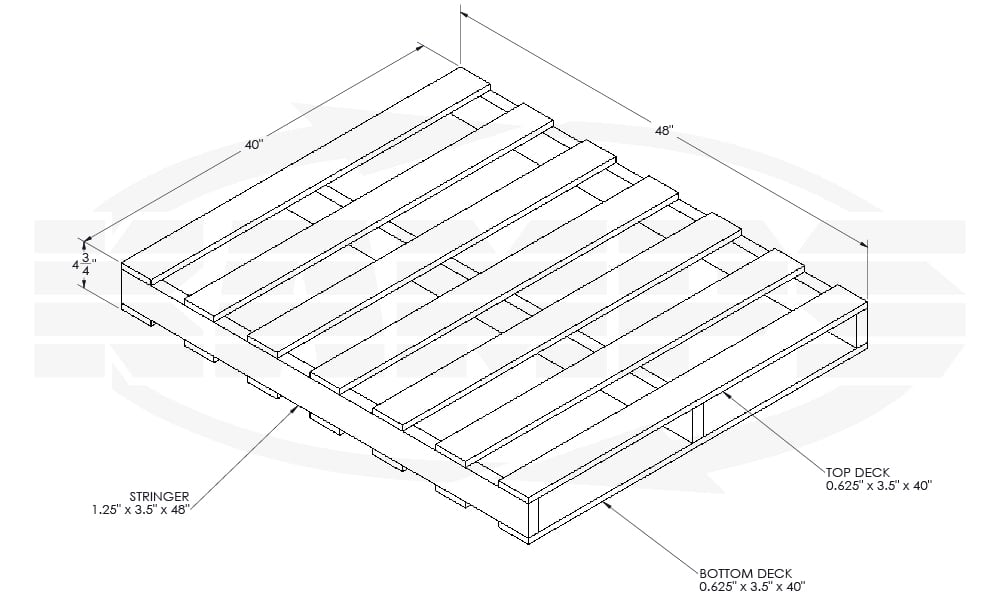

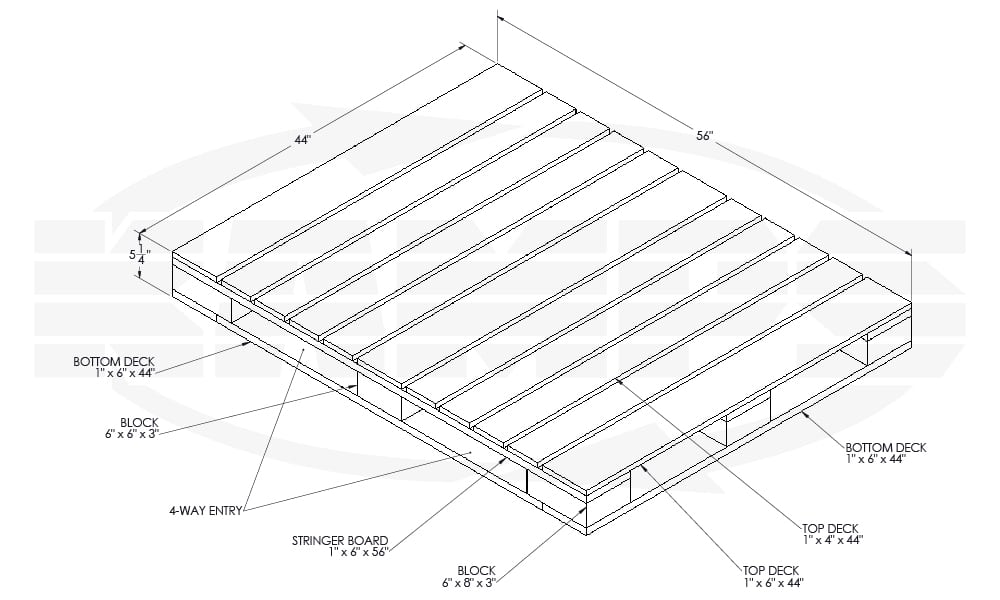

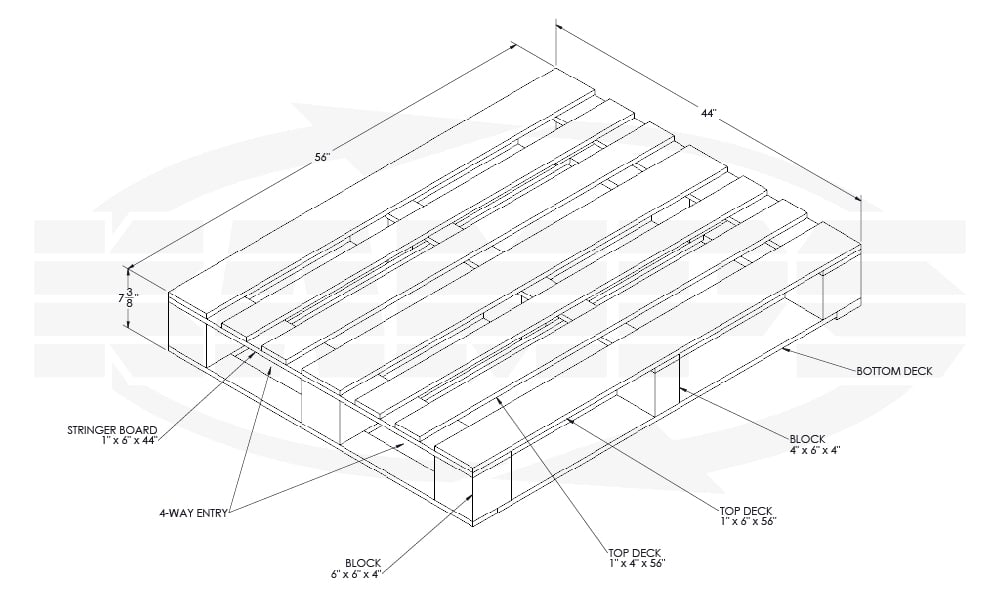

Block

Block Pallets are made from solid wood, plywood, or composite between the pallet decks or beneath the top deck. The difference from stringer pallets is that they have both top and bottom deck boards. This design allows for four-way entry, making them more accessible for forklifts from all sides. They can also be made without top or bottom boards. Block pallets are generally more durable than stringer pallets.

Skid

Skid Pallets are the simplest form of pallets, essentially being a single-deck load platform. What makes them different from Stringer and Block Pallets is the absence of a bottom deck. Skids are often used for heavy-duty applications and their simple design makes them lightweight and cost-effective.

Standard Pallet Modifications

A standard pallet can further be modified to accommodate various needs. These modifications usually occur on the pallet’s top and bottom deck boards.

Solid Deck

Solid Deck Pallets either have no gap decking or a single solid sheet of wood as the top surface, with no gaps between the boards. This offers a smooth and even surface, ideal for carrying stacking, and shipping unstable items. The solid deck pallet is typically used for bagged products or products with small packaging.

Double Face

Double Face Pallets have top and bottom deck boards, allowing for a more even distribution of weight. They come in two types: reversible and non-reversible. Reversible pallets can be flipped and used on either side, while non-reversible ones have a designated top and bottom. These pallets are suited for heavier loads and provide more stability during handling.

Winged Pallet

Wing pallets are unique in appearance due to the overhanging deck boards or “wings”. The purpose of the extra length on the deck boards is to allow pallets can better distribute the load and also hold larger or oddly shaped products. The extra length also allows for easier shrink-wrapping.

Double Wing

Double Wing Pallets extend the top and bottom deck boards beyond the stringers or blocks. Just like with the regular winged pallet providing better distribution, the double wing also allows shippers to use the other side in case of damage to one side.

Choosing the right Pallet based on your needs

Many industries, like the grocery industry, use standardized pallet sizes to help improve the efficiency of the shipping and distribution of their unique products. This has led to many different types of pallets commonly used across the world.

Below are some of the most common industry-specific pallets.

Grocery/GMA

Grocery/GMA Pallets are standardized pallets primarily used in the grocery industry. With specifications established by the Grocery Manufacturers Association (GMA), these pallets typically measure 48” x 40”. They are usually made of wood and designed to hold a variety of goods such as canned food, boxed items, and perishables. The standard size facilitates efficient handling, storage, and transportation in grocery supply chains.

Grade A Standard GMA

One of the available selections of GMA pallets is the Grade A otherwise known as #1. It is considered to be the highest quality of recycled pallet. There are no stringer repairs and are dry and free of contaminants as per Food Grade Standards.

Grade B Standard GMA

The other option available for GMA pallets is the Grade B, otherwise known as the #2 pallet. These pallets, often worn and discolored, may show signs of stringer repair and have block or plug repairs. The Grade B pallet is very popular due to the cheaper cost vs the Grade A.

Read more about GMA Pallet Specifications from our blog post here.

Glass

Glass Pallets are specialized pallets designed for transporting goods for the bottling industry. These pallets need to be exceptionally sturdy to make sure they maximize storage space and also support the extreme weight of filled bottles and cans. As such they are often custom-made to fit specific sizes and weights of glass products though the standard size is 56” x 44”.

Can

Similar to Glass Pallets, Can Pallets are tailored for the storage and transport of cans, soda, and PET bottles. Can Pallets still need the capability of holding extreme weight so they are also made with wooden blocks rather than the stringers that traditional pallets use. The Standard Size is 44” x 56” and they often have a flat, solid surface to provide stable support for cans and to prevent them from rolling or being damaged.

Read more about glass and can pallets from this blog post

Beverage

Beverage Pallets are designed to transport and store various beverage products, including bottled and canned drinks. The standard size for these pallets is 36” x 36” which allows beverage manufacturers to quickly and efficiently load and unload the smaller pallets from their trailers.

Automotive

Automotive Pallets are specialized pallets used in the automotive industry. They are designed to transport and store automotive parts and components. These pallets are often custom-designed to accommodate the unique shapes and sizes of automotive parts. The 48×45 pallet size is the standard used in the automotive industry.

Click here to read our Automotive Case Study

Chemical

Chemical Pallets are used for storing and transporting chemical products and given the hazardous nature of their cargo, these pallets are designed for safety, durability, and resistance to chemicals. With standards set in place in 1991 by the VCI (Verband der Chemischer Industry) in Germany and then later adopted by EPAL (European Pallet Association) they are often made from treated wood or sometimes high-density plastic that can withstand corrosion, contamination, and extreme conditions. Chemical pallets may also adhere to specific industry standards and regulations to ensure safe handling and storage of chemical products. To assist various industries in ensuring the appropriate selection of pallets for transporting chemicals, standardized dimensions and types have been established, each tailored to specific applications and handling needs, ranging from CP1 to CP9. There is also the 48×48 pallet which is usually only used in the chemical industry – used to store and transport drums.

Telecommunications

The 42×42 pallet is most commonly used in the telecommunications, paint, and technical coating industries. However, it was originally designed for the US Military to transport and store mortar rounds.

Watch our video below to learn more about choosing the right pallet for your supply chain.