The Case Study

This case study focuses on a large big box retailer and highlights a pallet recycling strategy Kamps implemented to increase cost savings, pallet utilization, and create pallet program transparency.

This case study highlights Kamps’ consultative approach to pallet solutions. The analysis and problem-solving process included in this case study is an example of the approach our experts take with every pallet program – large or small. It is also important to note that every program and supply chain is unique and the benefits and solutions in this process may not apply to every scenario. This is exactly why Kamps’ expertise and know-how are invaluable in regard to pallet program improvement and analysis.

What is Total Pallet Management (TPM)?

A total pallet management program is a specialized program that involves an outside pallet company handling all aspects of an organization’s pallet operations directly at your facility. This includes pallet sorting, repair, and redistribution.

The Situation

The customer was sending most of their used pallet inventory from inbound vendors to individual service providers (pallet recycling companies) through a store sweeps program. To replenish the pallet inventory needed to ship products or internal use, the customer was then purchasing a mixture of new and used pallets from various pallet vendors. In some cases, the vendors purchasing the pallets and selling the pallets back to the customer were the same.

Opportunity for Improvement

After a period of analysis, the Kamps team identified an opportunity for improvement in between the customer’s pallet recycling (sales) and pallet purchase stages; in particular to asset turnover time, cost savings, and space utilization. For example, an organization can typically waste between 15 – 25% of their possible shipping space by running an inefficient pallet program and nonoptimal packaging.

Our experts also found room for improvement in sorting store returns, sorting recycling, and eliminating large waste streams by creating a closed loop system.

The Solution

After further analysis, Kamps determined that the difference in dollars generated from pallet sales and dollars spent on pallet purchases justified an investment in launching a Total Pallet Management (TPM) On-Site program for the home improvement retailer. Kamps would provide labor, equipment, and expertise on-site. In return, Kamps would charge a small repair fee to every pallet repaired, and recycle pallets damaged beyond repair off-site.

Case Study Results

By implementing the TPM On-Site program, Kamps was able to provide a tangible cost saving on every pallet repaired, along with delivering faster asset turnaround* even compared to traditional repair-and-return programs. The faster asset turnaround time also led to increased possible shipping space and a safer warehouse environment. The elimination of non-value-added expenses, such as freight, also further increased the cost savings for the home improvement retailer.

*The time between exporting damaged pallets and receiving back repaired ones

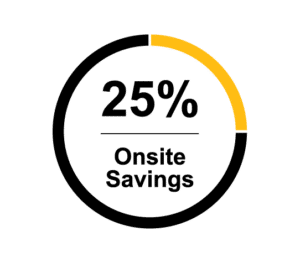

Cost Savings of 25% Per Site

Cost-savings based on repair cost per pallet at the time* during the on-site program, compared to a average finished goods spread.

*Disclaimer: Both repair costs and finished goods spreads are heavily influenced by market and economic pricing. While all Total Pallet Management on-site programs will carry a cost-saving opportunity, the cost savings achieved in the case study cannot be guaranteed.

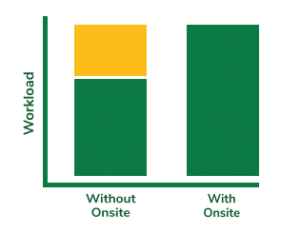

Time Savings

The on-site program eliminated the need for the retailer’s staff to dedicate time to managing pallets. This allowed the staff to focus on core responsibilities, increasing the overall efficiency of the warehouse operations.

24 Hour (or less) Asset Turnaround Time

Assets repaired On-Site have the potential to be reinserted into the supply chain within 24 hours (or less) of arrival at the facility.

Full Sorting Transparency and Visibility

Pallets sorted on-site provide full transparency on quality and quantity during the sortation and repair process. Assets repaired On-Site have the potential to be reinserted into the supply chain within 24 hours (or less) of arrival at the facility.